In an era where speed is the hallmark of achievement, sandwich panels shine as a smart and innovative choice in the world of construction. However, like other modern solutions, they come at a price. The elegant facade and attractive cost may conceal important details that could later become challenges affecting your entire project. Therefore, it's important to highlight not only their advantages, but also the disadvantages of sandwich panels, which can impact the project's efficiency and quality in the long run.

In this article, we won't sell you illusions. Rather, we'll reveal the flaws of sandwich panels in a clear and credible manner that will help you make an informed decision you won't regret. The difference between a sustainable project and one that collapses begins with the material you choose and the partner you rely on, like Myco.

Read also: Fire-resistant sandwich panels - Maico

What is a sandwich panel?

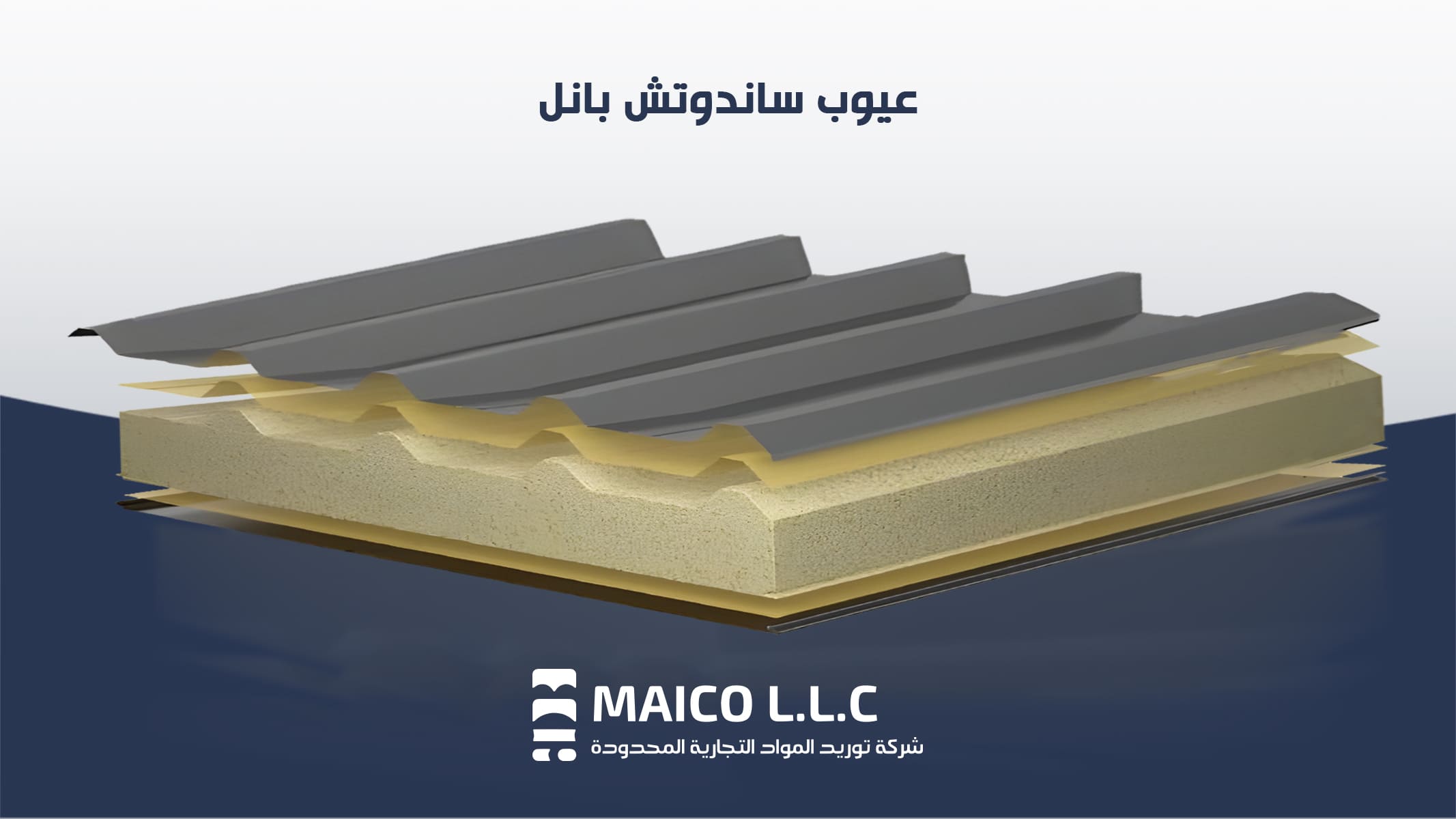

When engineering intelligence meets the need for speed and efficiency, sandwich panels emerge as one of the most prominent modern construction solutions. They are not just metal panels, but an integrated system consisting of two outer metal layers separated by a high-performance insulating core.

Sandwich panels are also lightweight and easy to install, making them a preferred choice for hangars, warehouses, insulated rooms, and even temporary and permanent buildings. It's a solution that saves time and reduces labor costs without compromising on insulation or quality.

However, just as every building material has advantages, it also has disadvantages that cannot be ignored. We will learn about the disadvantages of sandwich panels in detail below.

Disadvantages of sandwich panel

Despite the numerous advantages of sandwich panels, their use is not without its challenges. Some defects may not be apparent at first glance but become more apparent over time or with improper use.

These disadvantages vary depending on the manufacturing quality, installation method, and type of insulation used. In the following paragraphs, we will review the most prominent disadvantages of sandwich panels in a simple and straightforward manner, to help you make a more informed decision when choosing this material for your projects.

Read also : Myco Sandwich Panel Catalog: Your Smart Guide to Choosing the Best

Poor insulation in inferior species

Not all sandwich panels are equal in quality. Some cheaper types do not provide adequate insulation, allowing heat or sound to escape into the building. This results in energy loss and increased noise levels, negatively impacting comfort and heating or cooling efficiency.

Corrosive susceptibility in humid environments

If panels are not properly coated or treated, they are susceptible to corrosion over time, especially in areas with high humidity or close to the sea. This threatens the integrity of the structure and reduces its lifespan, especially if they are not coated with an anti-rust layer.

Don't fall for cheap prices. Myco offers sandwich panels that meet European quality standards, backed by advanced protective layers to resist moisture and harsh conditions. Contact us through the following:

- Mobile: +966551466334

- [email protected]

- Email: [email protected]

limited shock tolerance

In industrial applications or harsh environments, some panels may not withstand shocks or heavy loads due to their light weight. They are susceptible to damage or denting during improper storage, transportation, or installation, which can lead to deformations in the exterior appearance and reduced weather resistance.

The need for precise and professional installation

Any mistake in sandwich panel installation could lead to problems such as leaks, poor insulation, or even structural damage, which would require costly maintenance later on. Therefore, choose professional technicians for this step from the outset. This is where Myco comes in with its distinguished team, known for its sandwich panel installation expertise.

Difficulty in adjustment after installation

After the panels are installed, making any design modifications such as additional ventilation or electrical openings becomes complicated and may damage the structure.

Due to the nature of sandwich panels, it is difficult to make modifications such as installing electrical or air conditioning after installation, which requires careful planning in advance.

Therefore, it requires careful planning from the beginning. With Myco, you're in safe hands. They don't just sell, they provide a comprehensive installation service with a trained team that ensures quality implementation from start to finish.

high initial cost

One of the major drawbacks of sandwich panels is their high initial cost, as they require significant investment in materials and manufacturing. Although they offer speedy completion, their initial cost may be higher than some traditional building materials.

This poses a challenge for projects with limited budgets, especially when high-quality materials are required. However, don't forget that they save on insulation and maintenance costs in the long run.

Lack of qualified technicians in some areas

Not every technician or contractor has sufficient experience in sandwich panel installation. Despite the availability of materials, the lack of trained technicians can affect the quality of installation, highlighting the importance of choosing a company with experience in the field.

A lack of qualified personnel can lead to unsatisfactory results and structural problems in the future. This is where Myco's strengths shine once again. Not only do they provide high-quality panels, but they also guarantee a dedicated team covering all phases of the project, from design to implementation.

Read also: Sandwich Panel Dimensions | Specifications - Uses

How to avoid sandwich panel defects?

Avoiding sandwich panel defects doesn't mean abandoning them, but rather understanding them well and choosing the right type according to your project's requirements:

· Know the source, i.e. do not trust any product without approved sandwich panel specifications or a quality certificate.

· Rely on technicians with real installation experience, because most problems come from installation errors, not from the material itself.

You must choose the type of insulation appropriate for the nature of the place. Polyurethane is not like rock wool, and each has a specific function.

· Don't neglect regular maintenance, especially in humid or weather-prone environments.

Treat your sandwich panel like a long-term investment, one that starts with conscious choice and succeeds with careful monitoring.

Why is Myco the safest choice?

In a market filled with options and tempting offers, Myco stands out not only as a sandwich panel supplier, but as a reliable partner at every step of your project. Its products are manufactured according to the highest European standards and undergo rigorous testing to ensure insulation, strength, and resistance to climate conditions.

Most importantly, Myco doesn't sell you a product and then end the relationship. Instead, it provides technical support before, during, and after installation, protecting your investment from costly mistakes. Its experience with large and diverse projects means it knows exactly what you need. If you're looking for security, trust, real results, and world-class sandwich panel specifications, Myco is the right place.

In the world of modern construction, it is not enough to choose the fastest or cheapest material, but you must choose it with full awareness of its details, advantages, and disadvantages.

Sandwich panels may seem like an ideal option on paper, but they can become a real burden if they are not installed professionally, or if they are of poor quality.

Therefore, a smart decision doesn't just mean asking about price, but also about quality, performance, and longevity. This is precisely where the difference between a mere supplier and a company like Myco becomes apparent. Myco understands your project as much as it understands the importance of details, and provides you with a product that is worthy of your trust and that stands the test of time.

Read also : Sandwich panel sales companies - how to choose and search for the best ones

Top Frequently Asked Questions About Sandwich Panel Disadvantages

Can the sandwich panel be modified after installation?

Yes, the sandwich panel can be modified after installation, but it depends on the type of modification required.

Some simple modifications such as adding vents or installing new additions may be possible without having to remove the panels completely,

However, major modifications such as structural redesign or location change may require removing and reinstalling panels, which can result in additional costs.

Is sandwich panel suitable for all types of projects?

Sandwich panels are a flexible option suitable for many projects, such as industrial buildings, warehouses, and commercial centers. However, they may not be suitable for all applications, especially in projects that require superior thermal or sound insulation or high resistance to environmental factors.

Therefore, specific project needs and site conditions must be considered before making a final decision.

How do I ensure that the sandwich panel I buy is of high quality?

To verify the quality of the sandwich panel, you must start by examining the materials used in its manufacture, such as the type of rock wool or polyurethane used as insulation.

Panels must be made of rust- and corrosion-resistant materials to ensure longevity. It is also preferable to choose reliable suppliers who are well-known in the market and have recognized quality certifications.