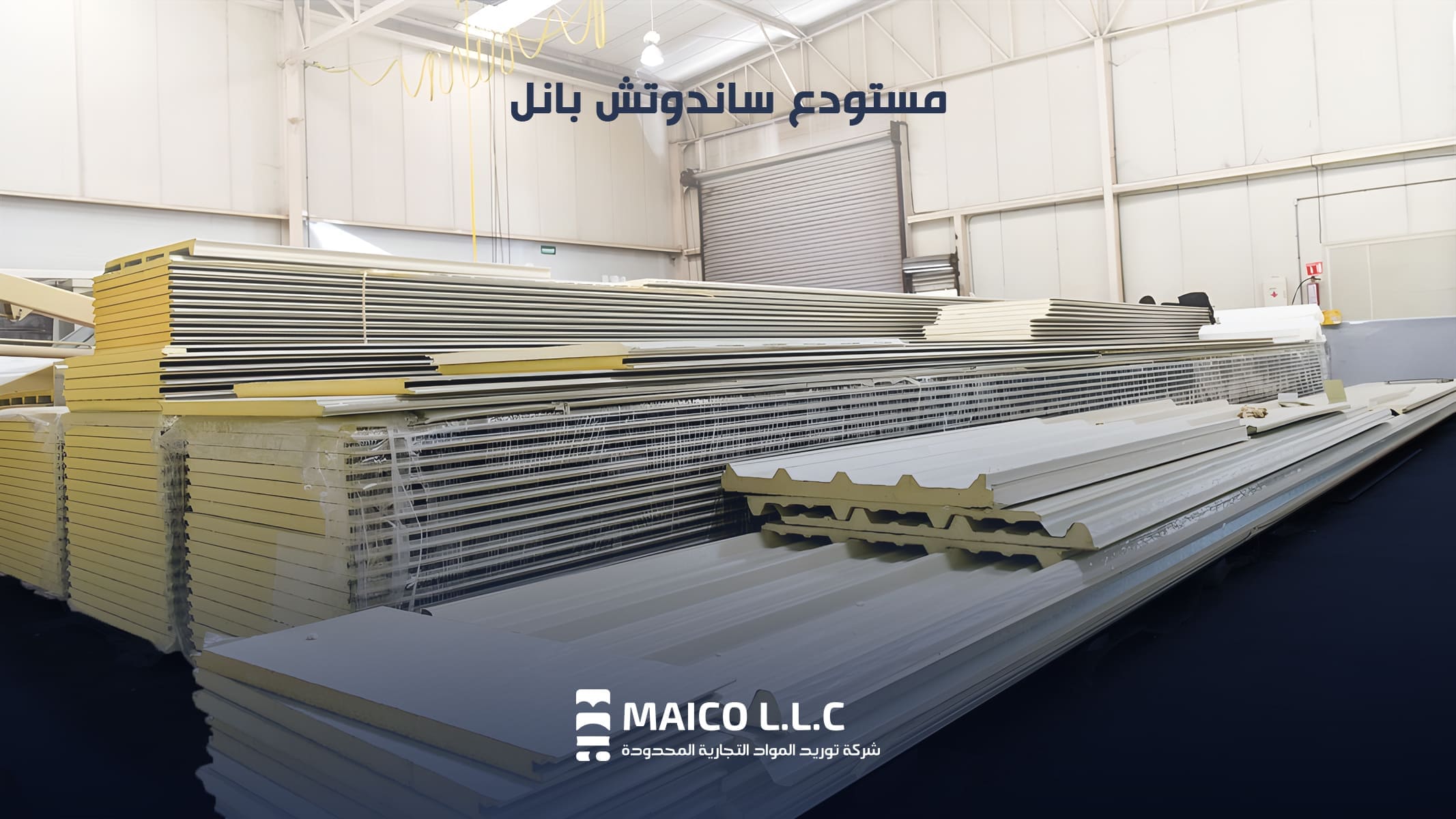

A sandwich panel warehouse is the essential starting point for any construction project requiring thermal insulation and efficient performance. With urban expansion and contractors and engineers relying on modern construction techniques, sandwich panels have become an ideal choice for constructing prefabricated buildings, warehouses, cold rooms, and more. With the increasing demand for this material, the need for specialized warehouses offering integrated services has emerged.

In this article, we'll take you on a tour of the world of sandwich panel warehouses, revealing their importance and the services Myco Limited offers in this regard.

First of all, what is a sandwich panel warehouse?

A sandwich panel warehouse is a storage facility constructed using sandwich panels as the primary material for walls, ceilings, and sometimes doors, instead of traditional building materials such as cement or brick.

Sandwich panel warehouses come in a variety of shapes, including:

- Traditional warehouses: rectangular with a hipped or gabled roof.

- Cold or freezing warehouses: High thickness sandwich panels with special insulation are used.

- Agricultural warehouses: for dry or refrigerated storage of crops.

- Temporary warehouses for projects or exhibitions.

This type of warehouse is a fast-installing and highly efficient construction solution that combines good thermal performance, light weight, and speed of implementation.

If you are looking for the best sandwich panel warehouse sales places , Myco is your best choice!

Learn with us about the features of a good sandwich panel warehouse.

A good sandwich panel warehouse is not only measured by its space, but also by its ability to maintain the quality of materials and facilitate their handling during storage and distribution.

The most prominent features of highly efficient sandwich panel warehouses are:

- Excellent thermal insulation: Maintains a stable temperature inside the warehouse, protecting products from damage due to heat or cold.

- Effective sound insulation: Reduces noise transmission, useful in industrial areas or near residential areas.

- Quick and easy installation: The warehouse can be built in a short period of time compared to traditional construction.

- Light weight: reduces the load on foundations, making transportation and installation easier.

- High resistance to moisture and corrosion: thanks to the treated metal materials that are resistant to environmental factors.

- Fire resistance: especially when using panels with rock wool insulation.

- Ease of expansion or dismantling: Parts of the warehouse can be easily dismantled and moved or the design modified.

- Modern and organized look: Gives the warehouse a sleek look that can be customized to suit the project's identity.

- Customizability: Thicknesses, colors, and insulation types can be selected depending on the nature of the stored materials.

- Low maintenance: It does not require complex periodic maintenance, saving time and costs in the long run.

- Cost-effective: It is a less expensive option compared to traditional construction, especially for temporary or medium-sized projects.

These features make the sandwich panel warehouse a pivotal point in the project's success, not only as a storage location, but also as a center that ensures the readiness and quality of materials before they arrive at the job site.

But what is a sandwich panel warehouse used for?

Sandwich panel warehouses are widely used in many industrial and commercial projects due to their insulating and durable properties.

Its most prominent uses include:

- Store food at proper temperatures.

- Warehouses for medicines and medical supplies to protect them from moisture and heat.

- Factories and production workshops that require fast and durable construction.

- Distribution and logistics centers that require large spaces and effective insulation.

- Farms and feed stores to withstand weather changes and preserve content.

These warehouses provide an economical and practical solution that efficiently meets modern storage needs.

Are there any technical specifications required when building this type of warehouse?

Yes, there are technical specifications required when building this type of warehouse, including:

- Choose the appropriate board thickness (from 4 cm to 15 cm depending on the type of use).

- Determine the type of insulation based on the project needs (heat? sound? fire resistance?).

- Use a well-designed steel support structure to withstand wind and weight.

- The presence of ventilation holes and a water drainage system for the roof.

- Seal joints tightly to prevent air or water leakage.

Myco offers a variety of solutions to suit all your needs and meet all your project requirements. Don't hesitate to contact us now!

Why choose a sandwich panel warehouse over others? Here's a comparison that'll help you decide.

If you're looking for a smart, fast, and flexible solution to build a warehouse that meets your ambitions, sandwich panels are your undisputed first choice:

- Want your project ready in days? Sandwich panel warehouses are installed lightning fast, while traditional warehouses take months.

- Worried about your goods getting too hot? Built-in thermal insulation helps keep your contents safe, without the need for any external accessories.

- Worried about high costs? Lightweight, minimal materials, and easy to install... The result? Lower costs and higher quality.

- A modular warehouse? Yes, you can expand, modify, or even move it entirely... But a traditional one? Get a contractor's number now!

- Ready to face the sun and rain? Insulated metal panels withstand harsh conditions, while concrete walls begin to crack over time.

- Looking for a stylish look? A clean interface, custom colors, and a customizable geometric design are all part of the package.

- Maintenance? Hardly needed! The treated materials are rust and moisture resistant, eliminating seasonal maintenance costs.

Myco provides the best sandwich panel warehouses.

When you're looking for a sandwich panel warehouse that offers the best solutions and high quality for everything related to sandwich panels for sale, look no further than Myco, the best place to sell sandwich panels:

- Myco is a leader in this field, offering sandwich panel warehouses equipped with the latest systems and technologies to ensure you have the best experience.

- What distinguishes Myco is not only its warehouses, but also its comprehensive services, which include a diverse sandwich panel catalog containing the finest sandwich panels for sale in various types and thicknesses to suit all project needs, with the ability to prepare panels according to the required sizes.

- Myco also guarantees on-time delivery of materials and sandwich panels for sale , while providing continuous technical support throughout the project.

- With over years of experience in the industry, Myco offers innovative sandwich panel solutions for sale at competitive prices, making it the first choice for contractors and designers seeking to ensure the highest levels of quality and efficiency in their projects.

If you are looking for a sandwich panel room , sandwich panel factory or sandwich panel warehouse that offers comfort, safety and quality, Myco is the perfect choice.